Grease

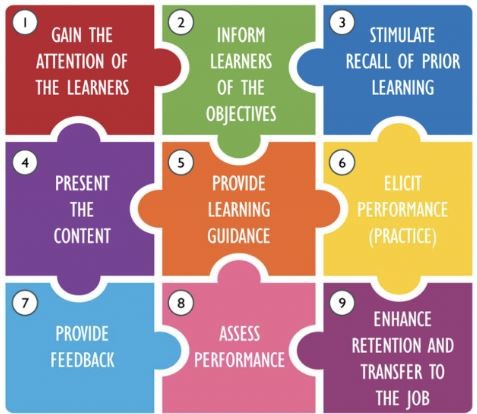

"Welcome to the module on grease. In this lesson, you'll learn about what grease is, the production process, the types of raw materials used, different types and their applications, and how to check grease, including the importance of its consistency and appearance. Let's get started!"

Module 1: What is Grease?

Script:

- "Grease is a semi-solid lubricant used in various mechanical applications to reduce friction and wear between moving parts."

- "It consists of a base oil, a thickener, and additives to enhance performance."

- "Grease is essential for the proper operation of machinery, especially in applications where liquid lubricants are impractical."

Question: "Can you explain why grease is crucial for machinery in certain applications?"

Module 2: Production Process of Grease

Script:

2.1 Base Oil Selection

- "The process starts with the selection of base oils, which can be mineral, synthetic, or vegetable oils."

2.2 Thickener Addition

- "Thickeners, such as lithium, calcium, or aluminum complexes, are added to the base oil to give grease its semi-solid consistency."

2.3 Additives Incorporation

- "Additives are then mixed into the grease to enhance properties like anti-wear, anti-oxidation, and water resistance."

2.4 Homogenization

- "The mixture is homogenized to ensure a consistent texture and performance."

2.5 Quality Control Testing

- "Grease undergoes rigorous testing to ensure it meets industry standards and performance specifications."

Question: "Why is the addition of thickeners essential in the production of grease?"

Module 3: Types of Raw Materials Used

Script:

- "The primary raw materials used in grease are base oils, thickeners, and additives."

- "Base oils can be mineral, synthetic, or vegetable oils, chosen for their lubricating properties."

- "Thickeners, such as lithium, calcium, or aluminum complexes, provide the semi-solid structure."

- "Additives, including anti-wear agents, antioxidants, and rust inhibitors, enhance the grease's performance."

Question: "What role do thickeners play in the composition of grease?"

Module 4: Types and Applications of Grease

Script:

4.1 Lithium Grease

- "Lithium grease is the most common type of grease, known for its versatility and high melting point."

- "It offers excellent lubrication and stability under a wide range of temperatures."

- Application: "Used in automotive, industrial, and household applications."

4.2 Calcium Grease

- "Calcium grease is known for its excellent water resistance."

- "It is suitable for applications where water contamination is a concern."

- Application: "Used in marine equipment, agricultural machinery, and water pumps."

4.3 Aluminum Complex Grease

- "Aluminum complex grease has a high dropping point and excellent load-carrying capabilities."

- "It is ideal for high-temperature applications."

- Application: "Used in industrial machinery, bearings, and heavy-duty applications."

4.4 Polyurea Grease

- "Polyurea grease is known for its long life and high-temperature stability."

- "It is suitable for sealed-for-life applications."

- Application: "Used in electric motors, automotive alternators, and high-speed bearings."

Question: "Which type of grease would you recommend for a high-temperature industrial application and why?"

Module 5: How to Check Grease

Script:

- "Checking grease involves inspecting its consistency, color, and appearance."

- "Grease should be smooth and consistent without lumps or separation."

- "The color of the grease can indicate its condition; fresh grease is usually bright, while contaminated or old grease may appear dark or dirty."

- "Ensure to check for any signs of contamination, such as dirt or metal particles."

Steps to Check Grease:

- "Remove a small sample of grease from the application area."

- "Inspect the consistency: it should be smooth and uniform."

- "Check the color: it should be bright and consistent."

- "Look for any signs of contamination, such as dirt or metal particles."

Question: "Why is it important to check the consistency and color of grease regularly?"

Conclusion

"Thank you for completing the module on grease. Understanding the types, production process, and proper inspection of grease is essential for maintaining the performance and longevity of your machinery. Regular checks and proper selection of grease can prevent breakdowns and ensure efficient operation."

No Comments